HRM Limestone vertical

Category:

Product Description

Technical Parameters

|

Model |

HRM2500 |

HRM2800 |

HRM3400 |

HRM3700 |

HRM4200 |

HRM1900 |

HRM1700 |

HRM1700 |

HRM1300 |

|

Grinding disc diameter(mm) |

2500 |

2800 |

3400 |

3700 |

4200 |

1900 |

1700 |

1500 |

1300 |

|

Yield(t/h) |

85~100 |

130~160 |

190~240 |

240~300 |

320~400 |

26~35 |

20~28 |

10~15 |

10~15 |

|

Raw material moisture(%) |

<8~10 < 15 |

||||||||

|

Raw meal fineness |

R0.08<14%(80Micron sieve) R0.08<12-12(80Micron sieve) |

||||||||

|

Raw material moisture(%) |

≤12 |

||||||||

|

Main motor power |

|||||||||

HRM vertical mill can be used to grind materials with a diameter less than 44mm on the rotary disc by rollers with certain pressure. It has advantages of high grinding efficiency, strong dry capacity, easily adjustable grinding size, low noise, low power consumption, simple process flow, low wear rate, low operation costs, etc.

It is mainly comprised by segregator, grinding roller, grinding disc, pressure device, speed reducer, electromotor, shell, and more.

Features of Vertical Mill:

1. High grinding efficiency and low power consumption. This kind of machine consumes 20-30% lower power. And with the growing of moisture content, its energy-saving effect will be more obvious.

2. Strong dry ability. Air is used to send materials, and the temperature of the air can be controlled according to the moisture content of materials. And this mill can be used to dry materials with moisture content as high as 12~15%, which is much higher than the special dryer.

3. Large feeding size. The feeding size can be as large as 5% of the diameter of the grinding diameter, that is, 40 to 100mm. Therefore, secondary grinding is unnecessary for large-scale and medium vertical mill.

4. Stable chemical composition and even particle size products.

5. Simple process flow and small in size. There is a segregator in the vertical mill, which makes powder separator and elevator unnecessary. Grinded dusty air can directly enter into the environmental protection equipment. So its process flow is quite simple and compact. Its structure size is only 70% of that of the ball mill, and its building space is only 50~60% of that of the ball mill.

6. Low noises, few dust, and environment friendly. There is no direct contact between the grinding rollers and grinding disc, so there is no impact sound caused by the colliding between the steel balls or between the steel ball and lining plate. Compared with ball mill, its noises are 20~25 decibels. Besides, our HRM and PRM vertical mills are sealed totally, so the whole system can work under the negative pressure condition. In this way, raising dust is vastly reduced.

7. Low metal wear rate, long service lifespan and high utilization rate of lining plate and grinding rollers. Because there is no direct contact and impact between metal components, its accessories have less wear and long service life. When this vertical mill processes medium hardness cement materials, its grinding rollers and lining plates can work normally as long as 8,000h.

As a professional manufacturer and supplier of vertical mill in China, Jiangsu Pengfei Group Co., Ltd can also provide you with various other machines, such as vertical raw mill, vertical slag mill, cement production line, cement grinding plant, industrial kiln and furnace, grinding equipment, crushing equipment, environmental protection equipment, cooling equipment, drying equipment, compound fertilizer equipment, packing machine, chemical equipment and electrical control system. Most of our products have passed the certification of ISO9000 and CE, and they have been quite popular among customers from as many as 60 countries and districts such as Germany, Russia, Brazil, Egypt, Iran, Japan, South Korea, Bengal, Pakistan, Turkey, Burma, Vietnam, South Africa, Columbia, Bolivia, etc.

Model HRM Vertical Mill - Buy Vertical Raw Mill ,

HRM Vertical Mill, Find Complete Details about Vertical Raw Mill from Other Construction Machinery Supplier or Manufacturer

If you need vertical mill, please don"t hesitate to contact us.

HRM Vertical Raw Mill,

Model HRM Vertical Mill - Buy Vertical Raw Mill ,

HRM Vertical Mill, Find Complete Details about Vertical Raw Mill from Other Construction Machinery Supplier or Manufacturer

HRM1900,HRM2400,HRM2800,HRM,3400,HRM3700,HRM2200,HRM1250,HRM1100,HRM24-28,HRM3400E,HRM1700M,HRM1300M,HRM1500M,HRM1700X,HRM3700E,HRM4200,HRM29.3M,HRM22/3,HRM34.3M,HRM27-29,HRM34.3.

It is a national high-tech enterprise and provincial innovative (pilot) enterprise, reinforced with several R&D organizations such as provincial enterprise technology center, Hefei Engineering Technology Research Center etc. And a good number of technical achievements of the company are at the international advanced level. Furthermore, it has won the second prize of the national science and technology progress for two times, provincial and ministerial science and technology progress award for 10 times, and various industry, group and local science and technology awards for numerous times.

Key words:

LATEST NEWS

Thank You for Your Attention to ZhongYa!

Send us your needs for your business, we have professional service team to answer you !

EP Service

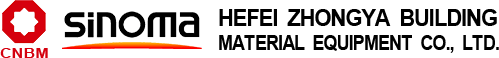

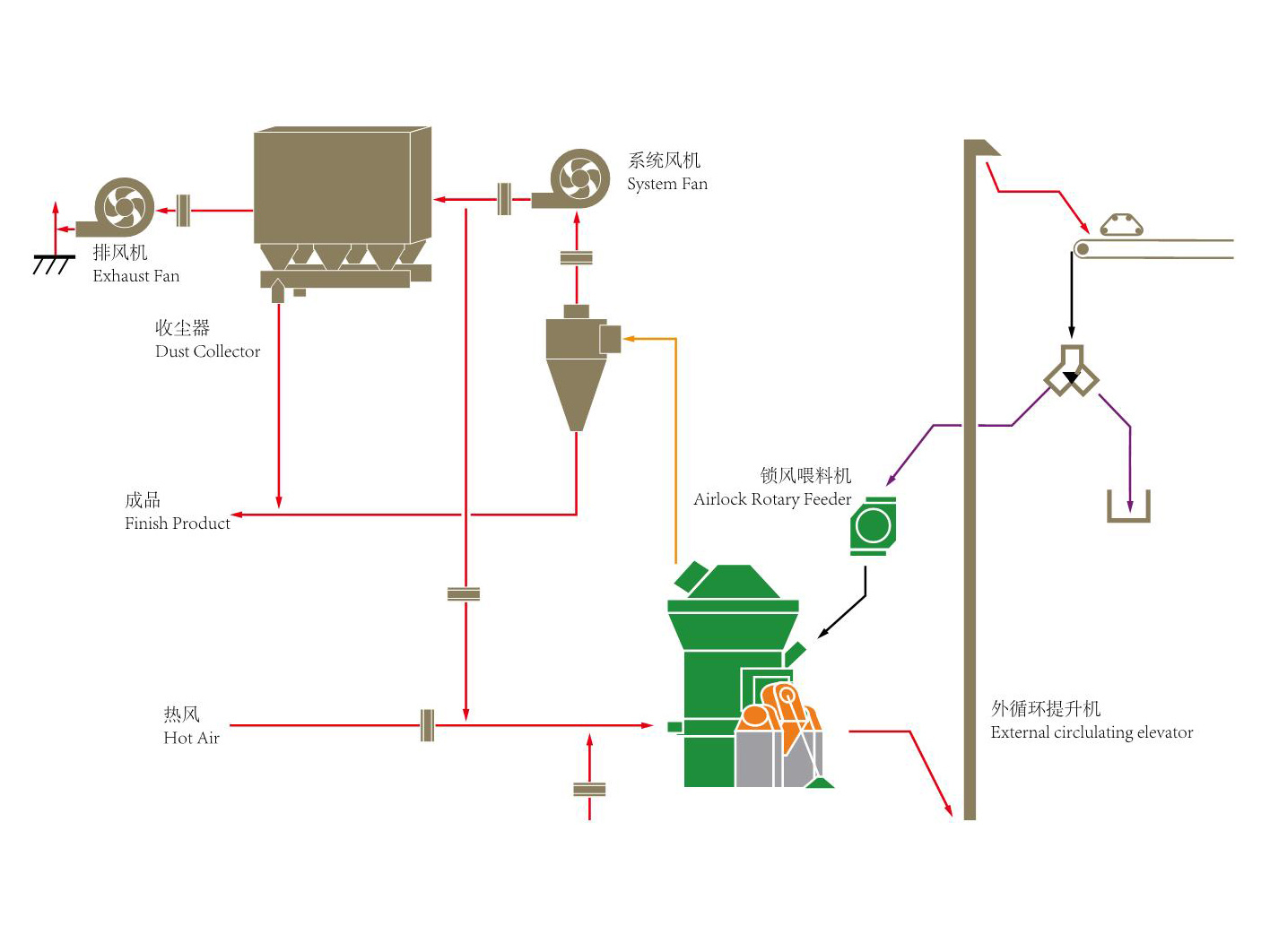

External circulating system (basically used for cement raw meal final grinding and clinker semi-final grinding)

Adopt external circulating elevator for material. circulation, reduce the system air pressure, significantly reduce energy consumption of the syetem .

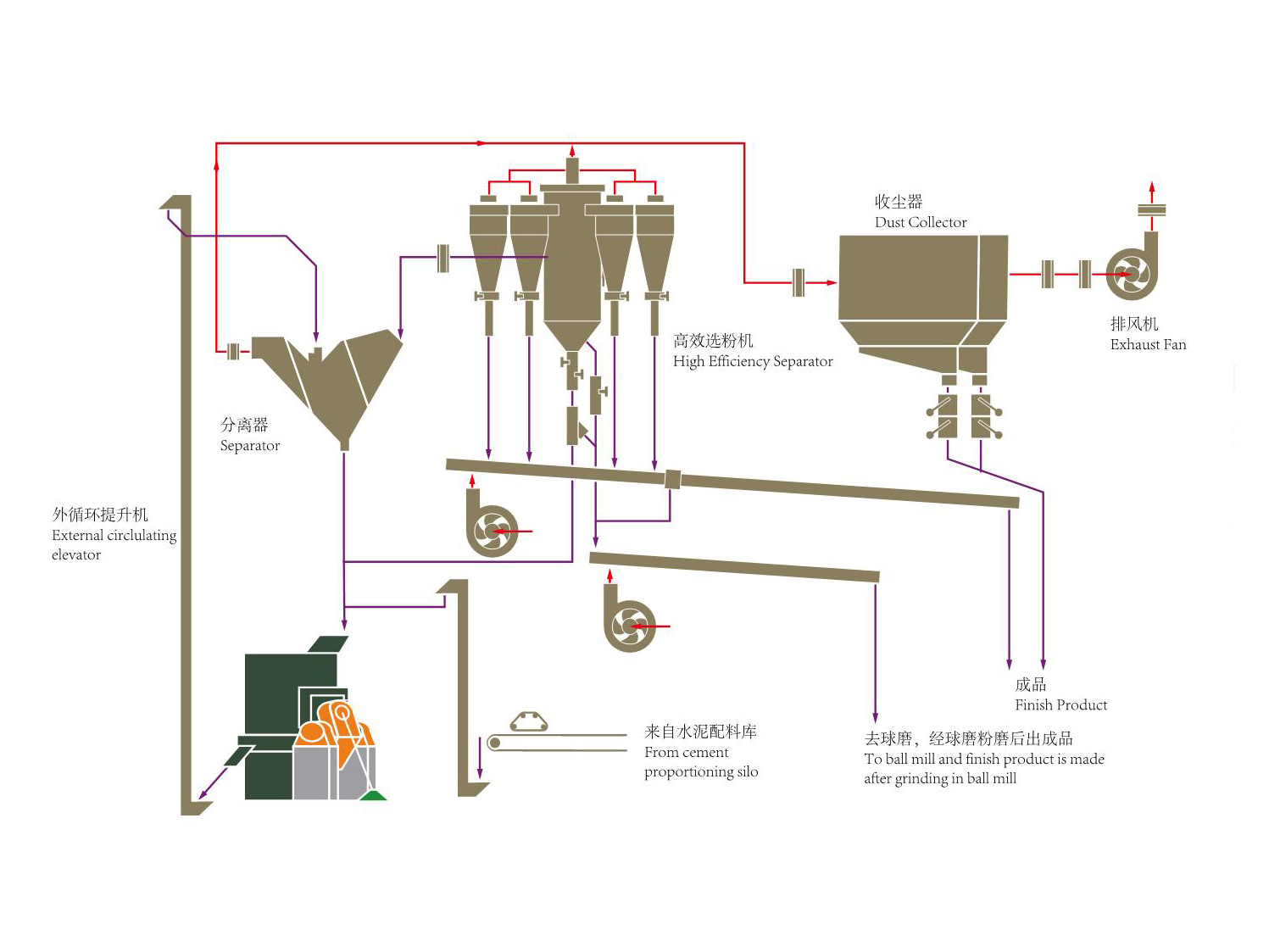

Single stage dust collecting system 1

The dust collecting device is adopted with explosion-proof bag filter and the discharge air enters into dust collector directly. This system reduces installation of numbers of equipments simplifies system configuration.

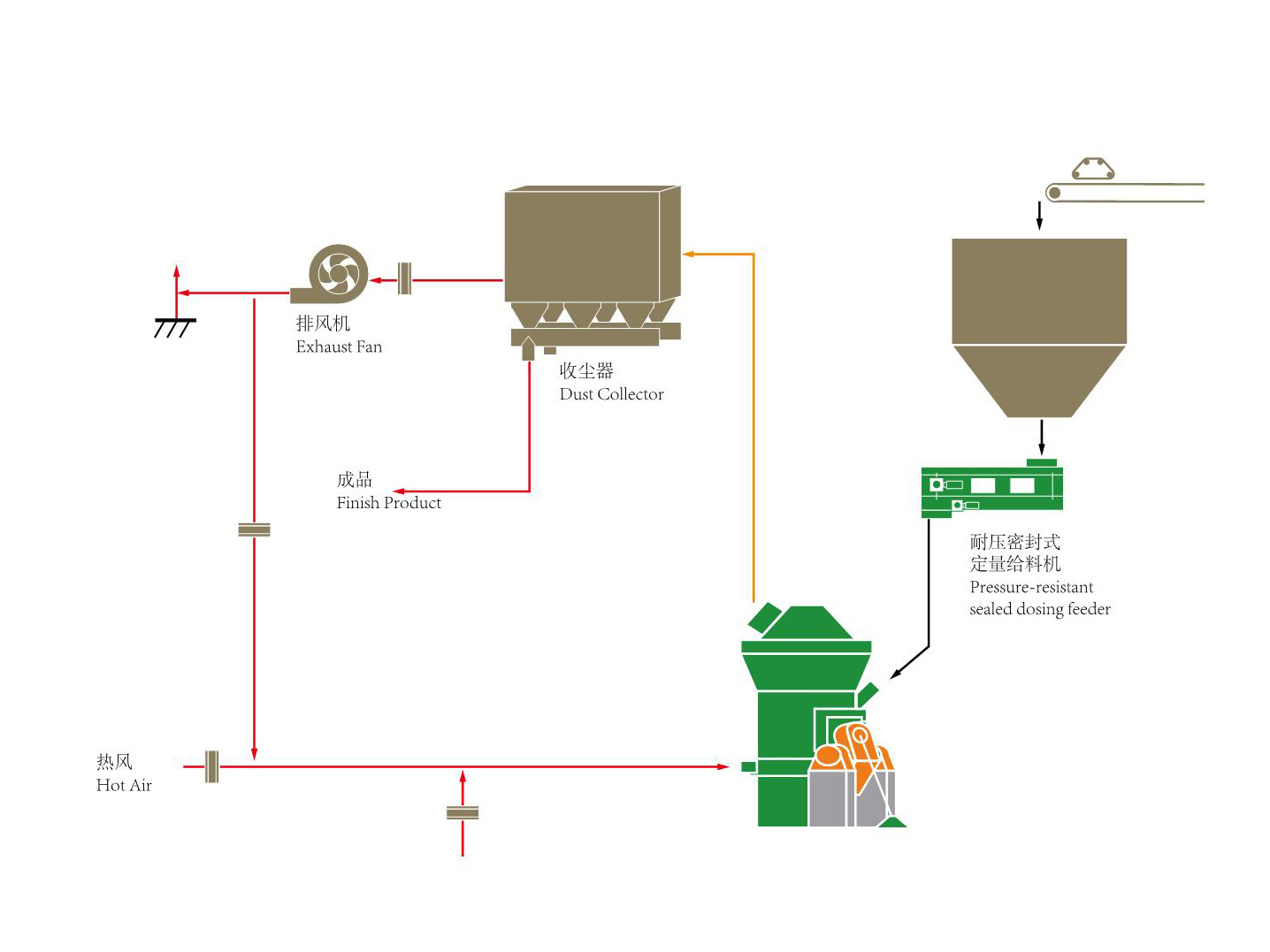

Single stage dust collecting system 2

The dust collecting device can be adopted with a high concentration. EP or bag filter, the discharging air enters directly into the dust collector. This system reduces the number of equipment and simplifies the system configuration.

2nd stage dust collecting system

Cyclone dust collector is adopted for collecting product. This arrangement is helpful to reduce the system's negative working pressure and air volume passing through the dust collector. EP or bag filter can be used as final dust collecting equipment..